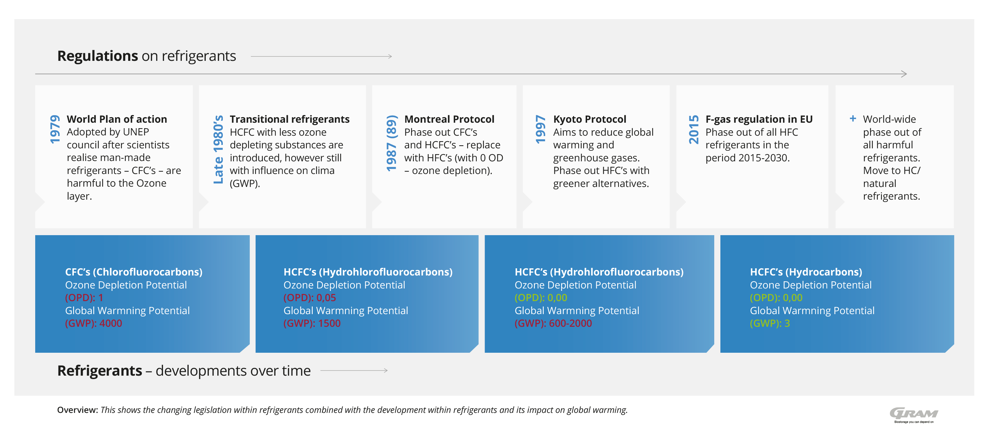

The Montreal Protocol of 1987 provisioned a phase-out of CFC and HCFC refrigerants due to their Ozone depletion potential and what we later learned to be global warming potential. They were replaced by a class of refrigerants which had a 0 ODP, these were classified as HFCs. HFCs became the norm and quickly replaced the traditional refrigerants due their ease of use/handling and efficiency. While HFCs have 0 ODP, their GWP is a wholly different matter, and while having a lower GWP than traditional refrigerants, HFCs contribute to global warming to such an extent that they were included as one of the six gasses regulated by the Kyoto protocol of 1997.

Regulations

Since the Montreal Protocol, steady and increasing governmental focus, regulation and legislation has been implemented to combat ozone depletion and global warming. In 2015 The European Union decided to push the green agenda further with Regulation (EU) No 517/2014 that aims to cut two thirds of all F-gases by 2030. This is mainly achieved by prohibiting the selling of equipment using F-gasses and imposing a limit to the sellable quantity of F-gases inside the EU.

Goals aligned

When regulation and business initiative go hand in hand, we see a much greater effect in the market:

The expected cumulative emission savings are 1.5 Gigatonnes of CO2 equivalent by 2030 and 5 gigatonnes by 2050. The latter number is more than the CO2 produced by a billion return flights from Paris to New York and more than the sum of all greenhouse gases emitted in the EU during one year (*Source EU)

Taking the above into consideration, we believe that we, as a company, have a responsibility to find better solutions for the environment, as global warming is a major concern moving forward. The regulation on fluorinated greenhouse gases, which is a part of EU’s Climate Action targets, is one of the areas that has been decided to improve.

Being part of the solution

At Gram BioLine we started adopting natural green refrigerants into our products over 20 years ago. Acknowledging that giving customers the “green” option at no extra cost was the best path to starting this migration to natural refrigerants, long before legislation on the subject came to light – we have stayed true to this and develop with sustainability as a focus to this day.

Reliability and efficiency in one

The use of natural Hydrocarbon refrigerants (HC) means ODP of 0.00 and GWP close to 0.00. At Gram BioLine, natural refrigerants have been a part of our mindset since our inception. Luckily, we see a lot of suppliers to the professional refrigeration industry, are implementing HC refrigerants to fight climate change. All Gram BioLine cabinets are available in hydrocarbon variants and continues to be a focal point going forward – providing the market with a green option at no added cost.

Hydrocarbon refrigerants consist of naturally occurring elements and have negligible or no impact on the earth’s climate should it escape into the atmosphere. Common hydrocarbon refrigerants for our application are:

- Propane (R-290)

- Isobutane (R-600a)

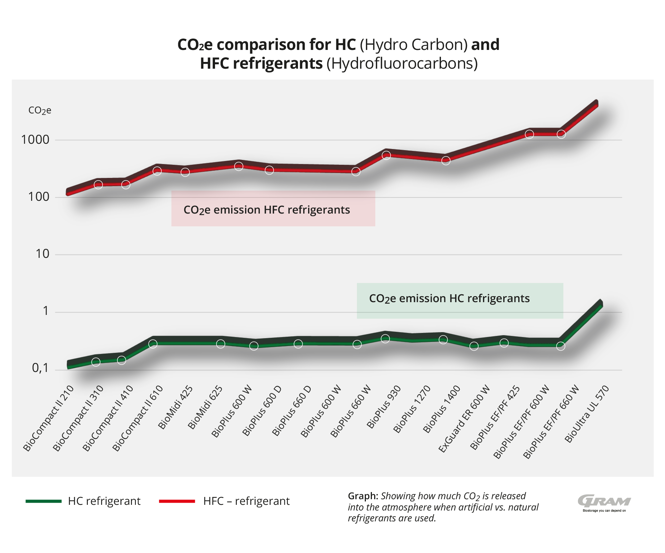

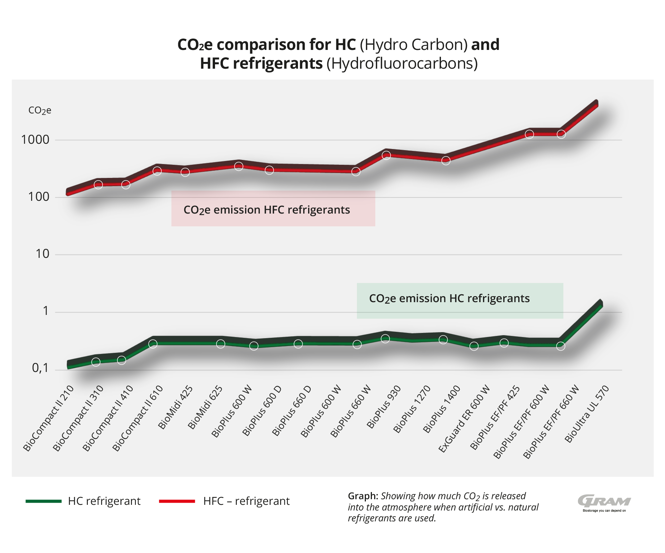

The graph shows the extreme difference, between using a HC (natural) refrigerant vs. a HFC refrigerant. The Gram BioLine products used are identical, however the difference in CO2e emission is times 1000 when using HFC refrigerants compared to natural refrigerants (HC). It means that one cylinder with 1 kg of R134A (HFC refrigerant) will burden the atmosphere with what quals to 1.43 tons CO2 of if released into the air, whereas 1 kg of R290 equals only to 3 kg of CO2.

Energy Consumption

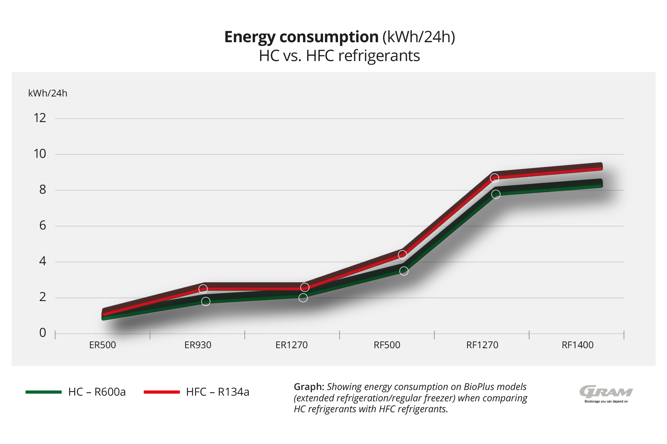

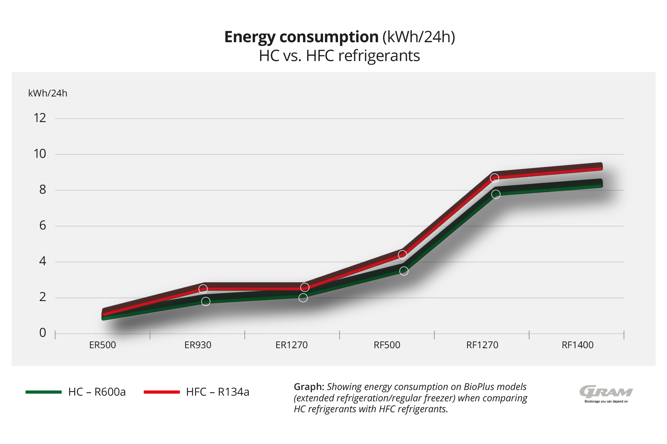

The graph below shows energy consumption when comparing HC (r600a) with HFC refrigerants (R134a). The benefits of natural refrigerants are, besides being more environmentally friendly, that they are also more energy efficient. Due to HC refrigerants’ outstanding thermodynamic properties as well as high latent heat of evaporation, we see increased efficiency compared to HFC/HCFC refrigerants.

Natural refrigerants are non-toxic, but comes with high risk of flammability, which means authorized personnel during installation and service is a required.

Reliability and protection of what is stored in our cabinets is key for our customers, that is a given. But luckily, reliability is never compromised by choosing a greener solution. Our refrigerator and freezers are built to our customer’s specifications for a wide range of applications ranging from general purpose to mission-critical storage. And on top of reducing CO2 emission, the natural refrigerants save energy because they are more efficient than its traditional (harmful) counterpart.

Source and links for more information

*Fluorinated greenhouse gases (europa.eu)

*EU legislation to control F-gases (europa.eu)

* EUR-Lex - 32009R1005 - EN - EUR-Lex (europa.eu)