ATEX

The yellow ATEX application sticker on our different model ranges enables placement in environments with potential explosive atmospheres, and storage of items that can cause potential explosive atmospheres.

The BioLine range of biostorage cabinets provides you with full ATEX compliance – both inside and outside the storage chamber – at no extra charge.

The following BioLine ranges below comply with EN/IEC 60079-15, which covers electrical apparatus for use in Category 3, Zone 2 locations where explosive gas atmospheres may be present.

Why should ATEX compliance be important to you?

- PERSONAL AND ENVIRONMENTAL SAFETY

- BETTER WORKFLOWS, GIVEN THE ABILITY TO SAFELY PLACE CABINETS IN WORK ENVIRONMENTS

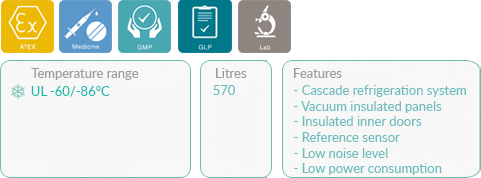

BioUltra

The BioUltra UL570 is an ultra-low-temperature freezer that operates safely at -86°C.

By utilising high-capacity components, cascade refrigeration system, latest generation vacuum insulated panel technology and insulated inner doors, the BioUltra cabinets are able to maintain safe and stable interior conditions when operating at -86°C.

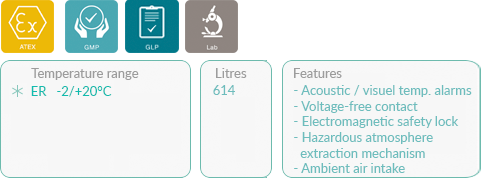

ExGuard

The ExGuard is designed for safe temperature controlled storage of items potentially emitting noxious, malodourous and /or explosive atmospheres. At the core, the ExGuard is envisioned to facilitate a safer work environment for users.

ExGuard increases work environment safety and allows placement in work environments by letting your existing ventilation system extract the hazardous atmospheres from the cabinet interior prior to you being able to access the interior.

BioPlus

This is our most advanced model, specifically designed to meet even the most stringent biostorage requirements. The compressor is mounted on top of the cabinet, and the interior is made entirely of stainless steel. BioPlus cabinets are available as full–height units with six different capacities.

BioMidi

This is our mid–range model, designed to comply with demanding biostorage requirements. The compressor is mounted at the base of the cabinet, and the interior sides are made of aluminium or stainless steel. All BioMidi models feature a high– specification control system.

This is our mid–range model, designed to comply with demanding biostorage requirements. The compressor is mounted at the base of the cabinet, and the interior sides are made of aluminium or stainless steel. All BioMidi models feature a high– specification control system.

BioCompact II

The BioCompact ll design is a general–purpose cabinet that features a forced air distribution system. BioCompact ll cabinets feature the same high– specification control system as the BioMidi model. BioCompact ll cabinets are available in sizes from full–height to under–counter models.

The BioCompact ll design is a general–purpose cabinet that features a forced air distribution system. BioCompact ll cabinets feature the same high– specification control system as the BioMidi model. BioCompact ll cabinets are available in sizes from full–height to under–counter models.

Scoping ATEX

In addition to the ATEX Directive 94/9/EC, which covers the safety requirements for equipment to be used in potentially explosive atmospheres, there is an additional European ATEX Directive 99/92/EC. This is also known as the "ATEX Workplace Directive" or "ATEX 137" and highlights what employers must do to minimise the risk to workers from explosive atmospheres.

Internal ATEX compliance is not sufficient to ensure a safe work environment..

A key distinction when assessing equipment adequacy in an ATEX environment, is the scope of its conformity.

When defining equipment compliance on refrigerators and freezers, we emphasise that it is not sufficient to only comply with ATEX inside the storage chamber. Without external compliance one essentially voids the option of opening the equipment (with potential explosive gases or vapours inside), as the exterior of the cabinet is not permitted to be exposed to this.

Given that one of the main functions of a refrigerator and freezer is to allow access to its stored items, this only speaks to the fact that having internal and external ATEX compliance is essential to the safety of an ATEX work environment.

All BioUltra, ExGuard, BioPlus, BioMidi, BioCompact II and BioBlood models provides you with full ATEX compliance – both internal and external – at no extra charge.

Category 3 - Equipment in this category is intended for use in areas in which explosive atmospheres caused by gases, vapors, mists or air/dust mixtures are unlikely to occur or, if they do occur, are likely to do so only infrequently and for a short period only.

Zone 2 - A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.